The information below is to highlight points of internal OEM discussion when considering EMS partners. Our aim with this outline is to provide some general guidance and topics for electronics OEM equipment firms (brand owners) to consider on your journey formulating extended contract electronics manufacturing supply chains. See also: OEM management of EMS RFQs

The information below is to highlight points of internal OEM discussion when considering EMS partners. Our aim with this outline is to provide some general guidance and topics for electronics OEM equipment firms (brand owners) to consider on your journey formulating extended contract electronics manufacturing supply chains. See also: OEM management of EMS RFQs

1. OEM’s come in different sizes and shapes (life cycle and type of company)

- Small to large companies

- Startups – mature companies

- Hardware vs software driven companies

- High gross margin versus low gross margin companies

2. What is your companies culture as it relates to outsourcing?

In your search results, you will be able to further target provider options by choosing End Markets, then selecting Go.

3. What is the driver of your selection decision?

- BoD-driven

- NPI-driven vs expanding current product line

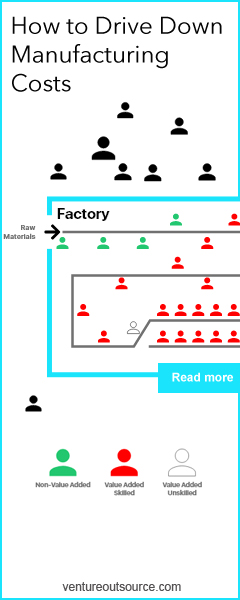

- Cost driven (see also: EMS global pricing vs should cost drivers)

- Second sourcing-driven

- Replacement of current source driven

- To go off shore-driven

- Driven as a result of an acquisition/divesture

4. What is your product portfolio?

- Low-high tech

- Low-high complexity

- Low-high cost

- Low-high volume

5. Geographies

- What are your geographic end markets (location)?

- Where are your offices/key teams/program management located?

- Does your NPI need to be done close to your development teams or can it be done at the main factory site?

6. What are your current landed cost (base line)?

In your search results you can further target other Industries and/or Services plus, you can add more geographies to your search.

7. Whom are your stakeholders for the sourcing decision?

SEE ALSO

Effective RFQ for EMS manufacturing programs

Differences between OEM, CM, CEM, ECM, EMS, ODM, JDM, design houses

8. What are the strength and weakness of your own team/company as it relates to the products/services you are outsourcing?

Get list of EMS manufacturers for your requirements (Its free)

Save time and money. Find quality EMS manufacturers. Fast. Venture Outsource has a massive, global database of contract electronic design and manufacturing capabilities. Speak with a Provider Advisor.

“Was able to very quickly find details on the important elements of setting up EMS and ODM partnerships, talked with an advisor for personalized info on quality providers matching our requirements while getting up to speed quickly about the industry and connect with key staff from like-minded companies and potential partners. Great resource.”

— Jeff Treuhaft, Sr. Vice President, Fusion-IO

Advisors tell you matches we find for your needs, answer your questions and, can share EMS industry knowledge specific to your industries and markets.