Contract electronics manufacturing and design firms use computer numerical control (CNC) automation machines and tools to achieve better control of customer product box build and system integration casings and enclosure design, function and features.

Contract electronics manufacturing and design firms use computer numerical control (CNC) automation machines and tools to achieve better control of customer product box build and system integration casings and enclosure design, function and features.

Essentially, CNC machines are automated processing of lathes, punch pressing, routers, drills, cutters and millers and grinding along an assembly line able to create forms, faceplates, enclosures…from various substrates ranging from metal to plastics and more.

For the past few years there has been a trend with demand for CNC capabilities exceeding supply of CNC services. See graph below for estimated 2014 v 2015 CNC machines supply v. demand.

Estimated 2014 v 2015 CNC machines supply v. demand

When comparing metal die casting v CNC extrusion, metal casings produced by die casting typically can have surface flaws and need special treatment. Die casting will cost less than CNC but do not typically achieve the same quality parts and enclosures produced by CNC extrusion.

In your search results you can further target other Industries and/or Services plus, you can add more geographies to your search.

And since metal casing design has become an important feature for hardware products and components like smartphones, handsets, cameras, batteries, processors…OEMs turn to design complexity capability CNC machining offers.

SEE ALSO

OEM engineering and product development validation for EMS production

Checklist for pilot box build system integration hardware products (PDF)

Understanding EMS provider quotes for box build systems integration

Case in point. An earlier report by UBS reports when smartphone manufacturer Xiaomi announced its Mi4, CEO Lai Jun talked in detail at Xiamoi’s product launch conference about the phone’s metal frame as a key feature.

Jun said the Mi4 requires 40 different processes and 193 different tooling steps to produce the stainless steel metal frame.

Similarly, smartphone manufacturer Coolpad Group (formerly China Wireless Technologies) produced the aluminum metal casing for its Dazen 1S product and promoted its CNC machining process as a key feature of the Dazen 1S, and highlighted the complex production processes, with the frame requiring four extrusions, five rounds of CNC machining and 45 machining processes.

Premium smartphones and metal casings

In addition to Xiaomi and Coolpad, some other smartphone makers using CNC machining in their supply chain for metal casings of their higher end hardware products include Samsung, Huawei, Lenovo, TCL, BBK, HTC, and ZTE to name several.

In your search results you can further target other Industries and/or Services plus, you can add more geographies to your search.

Demand for CNC capacity will likely continue as products compete based on design, features and functionality.

SEE ALSO

OEM plan for product prototypes and product development (PDF)

OEM new product launch specs in EMS manufacturing

Electrical cable and wire harness assembly constraints

One noteworthy company mentioned above adding significant CNC capacity according to UBS is Samsung while Hon Hai group’s number of CNC machines has declined.

Estimated 2014 v 2015 CNC machines by owner

Below, according to UBS estimates and company data, CNC capacity for the following companies.

Note in the pie chart comparison above that contract electronics provider Jabil has declined in CNC capacity according to UBS research. This is surprising given additive manufacturing capability is becoming the only differentiator among many EMS providers. To find EMS providers offering CNC services use our advanced EMS directory search here.

Industrial Electronics New Product Launch and NPI Management

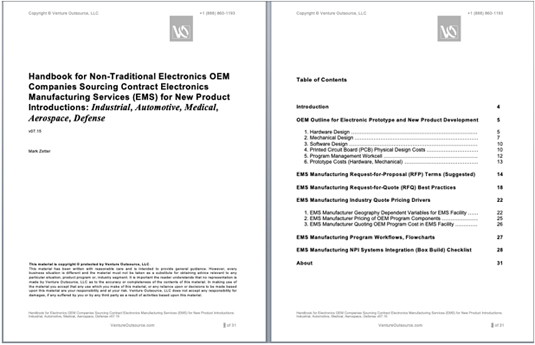

Learn more about industrial electronics new product NPI program launch and cost management in our 30-page handbook you can request here.

Designed for non-traditional electronics OEM companies, our handbook is divided into the primary topics below, with several topics going deeper, with detailed industry examples and clear suggestions and checklists for readers to consider:

- OEM Outline for Electronic Prototype and New Product Development

- EMS Manufacturing Request-for-Proposal (RFP) Terms

- EMS Manufacturing Request-for-Quote (RFQ) Best Practices

- EMS Manufacturing Industry Quote Pricing Drivers

- EMS Manufacturing Program Workflows, Flowcharts

- EMS Manufacturing NPI Systems Integration (Box Build) Checklist

Our handbook can help guide industrial electronics OEM manufacturers when formulating and benchmarking their new product launch roadmap and pricing strategy. Request this handbook.

Custom list of providers

Electronic OEM professionals reading this and wanting help locating contract electronic service providers matching your program and end market, Venture Outsource offers a free service. Speak with a Provider Advisor. Advisors have access to detailed information on listings in our global database and can help you compare provider service capabilities to better match your program needs. You can also click the button below.

Get list of EMS manufacturers for your requirements (Its free)

Save time and money. Find quality EMS manufacturers. Fast. Venture Outsource has a massive, global database of contract electronic design and manufacturing capabilities. Speak with a Provider Advisor.

“Was able to very quickly find details on the important elements of setting up EMS and ODM partnerships, talked with an advisor for personalized info on quality providers matching our requirements while getting up to speed quickly about the industry and connect with key staff from like-minded companies and potential partners. Great resource.”

— Jeff Treuhaft, Sr. Vice President, Fusion-IO

Advisors tell you matches we find for your needs, answer your questions and, can share EMS industry knowledge specific to your industries and markets.