Always ask how excess inventory is handled. Focus should be on “time-to-market” instead of “cost-to-market”. EMS company financial indicators are important. Quality not ranked as high as most think.

OEM new product introductions (NPI) can be considered more of an art than a science. With any piece of art the value it provides to viewers can vary widely, plus determining the value therein is a subjective process dependant on the people viewing it.

Like art, the NPI launch of new OEM products can also be considered a very subjective process, since there can be several different measurement methods of success when bringing new products to market.

The level of success of the OEM NPI product launch process can also vary widely by the process reviewer. However, once we apply objective methods that can be used by any OEM one can see this approach in coming to terms with ‘value’ can be repeated time after time to insure consistent, successful new OEM product launches. (See: Ineffective NPI time-to-market issues)

With the following objective approach, the most important element, and therefore decision process, to be made by the OEM relative to any NPI product launch becoming successful is the proper selection of the right NPI EMS provider.

If you look at the NPI launch process objectively, the following seven factors are essential when selecting the right NPI EMS provider. These seven success factors center around a “time-to-market” approach and getting the new product to market quickly compared to a “cost-to-market” approach which focuses on cost reductions or, getting cost out of the product.

New Product Launch and NPI Cost Management

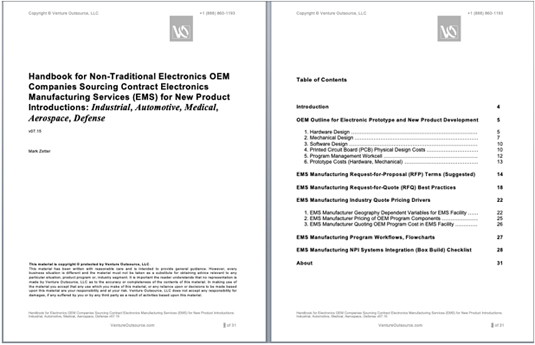

Learn more about new product NPI program launch and cost management with this Venture Outsource 30-page handbook you can request here.

Designed for non-traditional electronics OEM companies (industrial, medical, automotive, aerospace/defense), our handbook is also suitable for alternative electronics industries and is divided into the primary topics below, with several topics going deeper, with detailed industry examples and clear suggestions and checklists for readers to consider:

- OEM Outline for Electronic Prototype and New Product Development

- EMS Manufacturing Request-for-Proposal (RFP) Terms

- EMS Manufacturing Request-for-Quote (RFQ) Best Practices

- EMS Manufacturing Industry Quote Pricing Drivers

- EMS Manufacturing Program Workflows, Flowcharts

- EMS Manufacturing NPI Systems Integration (Box Build) Checklist

Our handbook can help guide electronics OEM manufacturers when formulating and benchmarking their new product launch roadmap and pricing strategy. Request this handbook.

Get list of EMS manufacturers for your requirements (Its free)

Save time and money. Find quality EMS manufacturers. Fast. Venture Outsource has a massive, global database of contract electronic design and manufacturing capabilities. Speak with a Provider Advisor.

“Was able to very quickly find details on the important elements of setting up EMS and ODM partnerships, talked with an advisor for personalized info on quality providers matching our requirements while getting up to speed quickly about the industry and connect with key staff from like-minded companies and potential partners. Great resource.”

— Jeff Treuhaft, Sr. Vice President, Fusion-IO

Advisors tell you matches we find for your needs, answer your questions and, can share EMS industry knowledge specific to your industries and markets.