Venture Outsource continues to see OEM equipment needs for EMS solutions providers certified in hazardous locations (HazLoc) manufacturing. Getting compliance can regularly take up to six months for manufacturers. Often times additional compliance is required specific to the type of product, program or market vertical.

Venture Outsource continues to see OEM equipment needs for EMS solutions providers certified in hazardous locations (HazLoc) manufacturing. Getting compliance can regularly take up to six months for manufacturers. Often times additional compliance is required specific to the type of product, program or market vertical.

Industrial programs

One OEM we worked with was looking for EMS providers meeting specific requirements for SMT, PCB assembly, box build and global fulfillment for their sensor and telemetry products for tank and cylinder monitoring in the energy, oil and gas, industrial markets. This program required strong engineering depth, strict safety certification processes, and detailed financial audit of the contract electronics solutions partner selected.

A second industrial OEM brand focused on electric drives / inverters for large, industrial electronics equipment involving high-complex design with variation in final product build. Units had ruggedized product capabilities based on precise torques, pressures, and heat dissipation with FGI able to operate in a range of environments from arctic to desert to ocean.

A third OEM produced a line of pressure sensors, length sensors, angle sensors, and flow sensors with design support and manufacturing and supply chain fulfillment by EMS and JDMs.

SEE ALSO

Contract EMS manufacturing RFQ best practices

Cable assembly demand exceeds solutions in Silicon Valley and beyond

It was important providers were chosen with expertise to precisely position LEDs, photodiodes…relevant to final product’s accuracy and competence – measuring microns when it came to torque sensors in systems integration and final assembly.

In your search results you can further target other Industries and/or Services plus, you can add more geographies to your search.

In contrast to the large, industrial equipment drives and inverters mentioned above (and ranging in size from a small microwave oven to the size of a family minivan), a fourth industrial OEM received a custom list of EMS providers for their nano RF project where the average size of the PCB measured 5×12 mm, contained four layers, with 70 microns of copper layers and a total, all layer thickness of .62 mm.

European theme and the horizon

One common theme for each of the client projects above is they each come from European companies in industrial electronics and controls industry positioning themselves to offset EU regional and global economic challenges so executives can become more competitive by leveraging partners serving their respective markets and regions where they serve their end customers. Today this is the United States.

Other programs we seeing increased interest in is ruggedized computers for factories and the field. Build specs for these are often demanding and with complicated screen with various glass laminates, coatings, layers with wires, and so on.

As technology becomes more embedded in our lives and in products we use in every industry manufacturers will continue to focus on design innovation that increases product platform embedded functionality and reduces product footprint.

Quality solutions providers with capabilities and industry requirements meeting OEM equipment program needs will help companies in Europe and elsewhere get their products to market faster.

Industrial Electronics New Product Launch and NPI Management

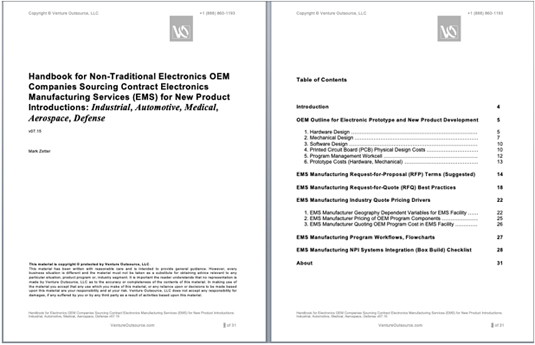

OEM companies can learn more about industrial electronics new product NPI program launch and cost management in our 30-page handbook you can request here.

Designed for non-traditional electronics OEM companies, our handbook is divided into the primary topics below, with several topics going deeper, with detailed industry examples and clear suggestions and checklists for readers to consider:

- OEM Outline for Electronic Prototype and New Product Development

- EMS Manufacturing Request-for-Proposal (RFP) Terms

- EMS Manufacturing Request-for-Quote (RFQ) Best Practices

- EMS Manufacturing Industry Quote Pricing Drivers

- EMS Manufacturing Program Workflows, Flowcharts

- EMS Manufacturing NPI Systems Integration (Box Build) Checklist

Our handbook can help guide industrial electronics OEM manufacturers when formulating and benchmarking their new product launch roadmap and pricing strategy. Request this handbook.

Get list of EMS manufacturers for your requirements (Its free)

Save time and money. Find quality EMS manufacturers. Fast. Venture Outsource has a massive, global database of contract electronic design and manufacturing capabilities. Speak with a Provider Advisor.

“Was able to very quickly find details on the important elements of setting up EMS and ODM partnerships, talked with an advisor for personalized info on quality providers matching our requirements while getting up to speed quickly about the industry and connect with key staff from like-minded companies and potential partners. Great resource.”

— Jeff Treuhaft, Sr. Vice President, Fusion-IO

Advisors tell you matches we find for your needs, answer your questions and, can share EMS industry knowledge specific to your industries and markets.