Should OEMs consider a tier-1 EMS provider’s interest in their business an accomplishment? If you think an EMS provider will throw you out when his factory gets full, you’re probably correct. Ideal percentage of your OEM business in an EMS provider’s facility is 10% to 15%.

Today, having the right EMS partner can be a significant part of a electronics product’s success or failure and therefore is often of critical competitive importance. Understanding the EMS landscape is important in selecting and understanding your EMS partner.

No one person can speak with authority for every EMS situation, but I can relay over 20 years of direct experience. In future articles I will change sides of the OEM-EMS negotiation table.

Prepared OEMs can’t be sold on solutions they don’t need

In the EMS sales process I have always instructed EMS sales staff to emphasize the service or feature that is a weakness in other, competing, EMS providers where the potential customer has already toured or is contemplating. (Read: The EMS site visit, The ODM site visit)

We then attempted to highlight the importance of this differentiation, and what it means to the OEM.

If the OEM did not properly document their hierarchy of needs, it would then be easy to turn a ‘feature’ into a ‘need’ thus our company into an EMS front-runner in that OEM’s EMS partner search.

Features are great, and in some cases they can solve a real problem on the OEM’s list of needs, but features are more often an undue distraction to the OEM’s core objectives.

In your search results, you can further target your Industry/or Services.

Having clear objectives, before beginning an EMS partner search, is the best tool in completing a successful electronics outsource manufacturing contract that matches the OEM’s business requirements.

When developing an OEM’s list of needs, the focus should be looking no more than three years ahead and with most important OEM needs being the present and near-future needs. Tomorrow’s aspirations are best realized by successfully executing against today’s challenges. In the final analysis, beyond three years should of course be considered, but with less weight.

No OEM is that unique

Electronics OEMs are usually excited about the newness of their products. Perhaps some of the technology incorporated is truly new, however, the portion of truly new technology in comparison to the whole is generally very small.

If it isn’t, you may be one of those companies that just can’t or shouldn’t outsource.

OEMs should not place an inordinate amount of value on the uniqueness of their product for two reasons: The first is that all technology is built on previous technology. It is quite likely EMS providers are currently, or have in the past, built something similar.

In your search results you can further target other Industries and/or Services plus, you can add more geographies to your search.

The second reason is specialists are usually not very good at the general level, and vice versa.

If you can’t ship your product because a detail has been missed, it matters very little what the detail is.

Try to find an EMS provider that can handle the entire OEM program but, if your product needs to be divided into areas of expertise, do it. It will not cost more from a management stand point in the long run. The additional planning expense will be saved in the cost of reacting to problems created by having the wrong single-source EMS provider.

The truth about global EMS providers

Contrary to what global EMS companies marketing directors and business development executives say, there is no true global EMS solution. Until EMS companies figure out how to structure individual site P&L objectives to align with overall EMS corporate objectives, there is only a collection of smaller EMS divisions or business companies under a single EMS corporate name.

And, in this collection of companies there are very good performers and there are very bad performers.

Each site should be looked at individually. OEM customer references provided by any EMS provider need to be site specific.

If your OEM program to be outsourced has good volume to put in each site there will be less to worry about; however, if you plan to use an EMS facility for depot repair work, or low volume, for instance, you will likely encounter problems.

This type of work / services provided by EMS companies is often forced onto a particular factory under the EMS corporate umbrella to help the EMS provider win the OEM program. Often times contracts for this work type is priced at below break-even for EMS providers.

Given that personal income incentives for the general manager at any particular EMS provider’s individual site are based on profitability, you can imagine the level of priority (think: zero) this type of work gets. It becomes a festering problem that perpetually appears on the monthly and quarterly performance reviews.

There are, of course, exceptions to this scheme such as an EMS provider’s new product introduction (NPI) facility transferring the OEM program to a low-cost regional facility once the program reaches suitable volumes. However, even these sites should be evaluated on their individual merits.

Size matters when it comes to EMS service

I have never understood why some OEM’s consider it an accomplishment for a tier-1 EMS provider to be interested in their business. It is true that EMS providers have supported a few start-ups that are today’s household names.

It is equally true EMS providers have supported far more OEM companies that have failed, or have fallen significantly short of everyone’s expectations.

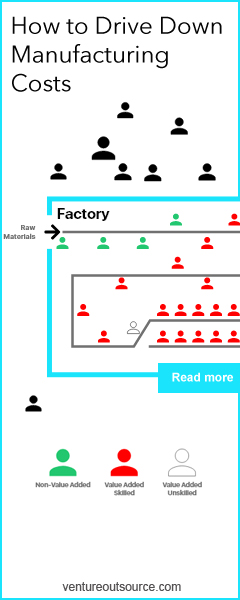

It is important for OEMs to align themselves with EMS providers of the proper size to have the best success.

If you think an EMS provider will throw you out when their factory gets full, you are probably correct. I wish I had a nickel for each time this was debated every time an EMS facility started to reach capacity.

The ideal percentage your OEM business should represent in an EMS facility is 10% to 15%. This is enough to get full attention, but not enough to dramatically impact a facility with forecast fluctuations.

All EMS facilities are doing business with smaller OEM programs, but their goal is to get these programs up to 10% by organic growth, or through their ability to win a larger portion of the OEM’s existing business.

If OEM executives feel there is no way their company could ever represent 10% of an EMS facility’s revenue, moving to a smaller EMS provider might improve the quality of service an OEM receives.

What are your thoughts? Leave your comments below.

Get list of EMS manufacturers for your requirements (Its free)

Save time and money. Find quality EMS manufacturers. Fast. Venture Outsource has a massive, global database of contract electronic design and manufacturing capabilities. Speak with a Provider Advisor.

“Was able to very quickly find details on the important elements of setting up EMS and ODM partnerships, talked with an advisor for personalized info on quality providers matching our requirements while getting up to speed quickly about the industry and connect with key staff from like-minded companies and potential partners. Great resource.”

— Jeff Treuhaft, Sr. Vice President, Fusion-IO

Advisors tell you matches we find for your needs, answer your questions and, can share EMS industry knowledge specific to your industries and markets.