In today’s hyper-competitive business world, manufacturers are increasingly looking to outsource their manufacturing needs to contract electronic manufacturing service (EMS) providers. While outsourcing can offer a number of benefits, it is important to conduct a cost-benefit analysis to ensure a positive return on investment (ROI) before making the decision to move forward with a requesting quote pricing for your contract EMS outsourcing program.

A cost-benefit analysis is a systematic process that weighs the costs of a project or program against its benefits to determine its overall value. When it comes to contract EMS manufacturing, the costs and benefits can be divided into several categories.

Costs

Direct costs: These are the costs that are directly associated with the contract EMS program, such as the cost of manufacturing, materials, shipping, and direct labor.

Indirect costs: These are the costs that are not directly associated with the contract EMS program but can still impact the bottom line, such as the cost of indirect labor staffing for functional groups supporting production such as quality control, corporate supply chain training, and the opportunity cost of not having in-house manufacturing capabilities.

Benefits

The primary benefit of outsourcing manufacturing to a contract EMS manufacturing provider is the potential cost savings. By outsourcing, companies can save on the cost of materials, labor, and equipment, as well as reduce overhead expenses. Read more about Venture Outsource costing modelers.

Expertise and flexibility: Contract EMS providers often offer specialized expertise and capabilities that can be leveraged to improve product quality and reduce time-to-market. In addition, contract manufacturers can offer greater flexibility in manufacturing processes and capacity, which can be particularly beneficial for small or mid-sized equipment manufacturers with fluctuating demand.

Risk mitigation: Contract EMS providers can help mitigate risks associated with manufacturing, such as supply chain disruptions, quality issues, and compliance with regulations.

RELATED

How to build EMS program cost modelers (PDF)

Our costing modelers and training labs

This can be particularly valuable in industries such as MedTech, automotive, military and defense, industrial, and aerospace electronics, where quality control and regulatory compliance are critical.

Meanwhile, roughly 70-80% of all contract manufacturing agreements fall under four different pricing models:

- Fixed materials pricing

- Component cost pricing

- Cost plus pricing (fixed price)

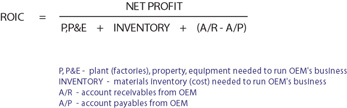

- Return on invested capital pricing (ROIC), where:

To ensure a positive ROI for a contract EMS program, decision makers must carefully consider each of these factors and conduct a thorough cost-benefit analysis.

Below are some key steps to follow:

Get list of EMS manufacturers for your requirements (Its free)

Save time and money. Find quality EMS manufacturers. Fast. Venture Outsource has a massive, global database of contract electronic design and manufacturing capabilities. Speak with a Provider Advisor.

“Was able to very quickly find details on the important elements of setting up EMS and ODM partnerships, talked with an advisor for personalized info on quality providers matching our requirements while getting up to speed quickly about the industry and connect with key staff from like-minded companies and potential partners. Great resource.”

— Jeff Treuhaft, Sr. Vice President, Fusion-IO

Advisors tell you matches we find for your needs, answer your questions and, can share EMS industry knowledge specific to your industries and markets.