Electronic contract manufacturing (outsourcing) is a networked business model benefiting electronic OEM equipment manufacturers with valuable benefits provided by EMS manufacturers, (but with some unstated costs like the loss of control and visibility). Loss of control can be OEMs (and EMS firms) overpaying vendor and supplier purchasing invoices, incorrectly billing OEM customer invoices (by EMS manufacturers), inaccurate (over or under) accruing reserves, EMS manufacturer over or under-performing on OEM customer program specs and commitments, and more.

Add to the above, whether OEM or EMS enterprise, another challenge is tying together proper alignment between the manufacturer’s financial functional groups and manufacturing operations – with the former typically taking a longer-term perspective while also not have the insight into operations that the manufacturing teams are exposed to immediately on a day-to-day basis.

Finance departments responsible for proper manufacturing compliance are tasked with effective identification and reporting of changing product value and manufacturer risk elements in the global enterprise supply chain.

Manufacturer financial statement restatements

Several studies over the years by the US General Accounting Office, Center for Audit Quality, PwC, The Deloitte Institute for Audit Innovation & Quality, Huron Consulting Group and others have revealed over the years that manufacturers have more financial report restatements than any other industry and citing inventory quantities and valuations, reserves and contingencies, and revenue recognition as primary reasons and each difficult to monitor properly in global, contract manufacturing business models with many moving parts.

Part of this is because of the [growing] use of outsourced, contract manufacturing EMS business models which involves many third-party, individual organizations fulfilling OEM customer demand tied to extensively networked EMS manufacturing supply chains.

The American Institute of Certified Public Accountants (AICPA) identifies ‘restatement of previously issued financial statements to reflect the correction of a material restatement due to fraud or error’ indicating a material weakness in the manufacturer’s internal controls.

Manufacturer financial restatements can drive down shareholder and investor confidence, jeopardize reputations of board members/outside directors and organizations and, eat up valuable resources and limited time which manufacturers could otherwise allocate elsewhere.

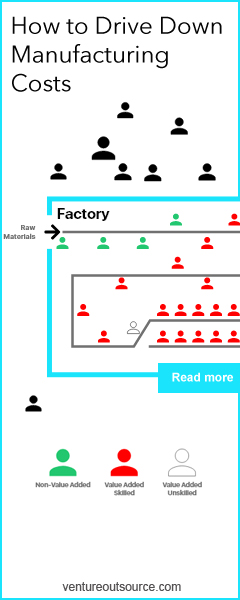

Manufacturers wanting to minimize errors tied to purchasing and various stages of product materials production and inventory should start with ongoing identification of potentially susceptible areas where financial reporting processes can go sideways. Materials cost of goods sold (MCOGs) and inventory (raw, WIP and FGI) make up a large part of your costs and liability.

PCNs and better cash conversion

Cash conversion is important to every organization. The high-tech, contract EMS manufacturing services industry is comprised of complex products with increasingly short product lifecycles, dynamic demand, considerable numbers of third-party partners, and significant leveraging of outsourced processes and services, leaving EMS manufacturers and their OEM customers especially exposed to risks inherent in highly leveraged (networked) outsourcing environments.

In your search results, you can add more Geographies, add more Services plus Industries to customize your search.

Manufacturers able to capture, integrate and maintain history of related changes to materials, BOMs and product programs and transactions – in real time – will be ahead of the curve. Predictive or ‘active’ vs passive PCN services are business critical. “Because once the PCN is announced you’re already late”, says one commodity manager for a leading European manufacturer.

Manufacturers view PCN management services as a profit protection and recovery tool and, aligning with corporate compliance mandates. In-process control vs after-the-fact scrambling to put out costly fires.

Manufacturing decision makers in commodity and supply chain management, purchasing, category management and corporate and operations finance, compliance and auditing, can save their organization millions, even billions, of dollars with real-time PCN management capabilities.

Manufacturing decision makers seeing the connection between compliance and the benefits of more informed operational decision-making will rise above their colleagues and competitors.

Get list of EMS manufacturers for your requirements (Its free)

Save time and money. Find quality EMS manufacturers. Fast. Venture Outsource has a massive, global database of contract electronic design and manufacturing capabilities. Speak with a Provider Advisor.

“Was able to very quickly find details on the important elements of setting up EMS and ODM partnerships, talked with an advisor for personalized info on quality providers matching our requirements while getting up to speed quickly about the industry and connect with key staff from like-minded companies and potential partners. Great resource.”

— Jeff Treuhaft, Sr. Vice President, Fusion-IO

Advisors tell you matches we find for your needs, answer your questions and, can share EMS industry knowledge specific to your industries and markets.